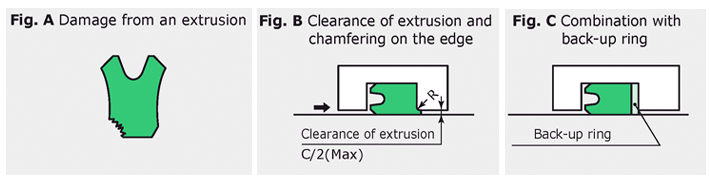

1.Damage from an extrusion

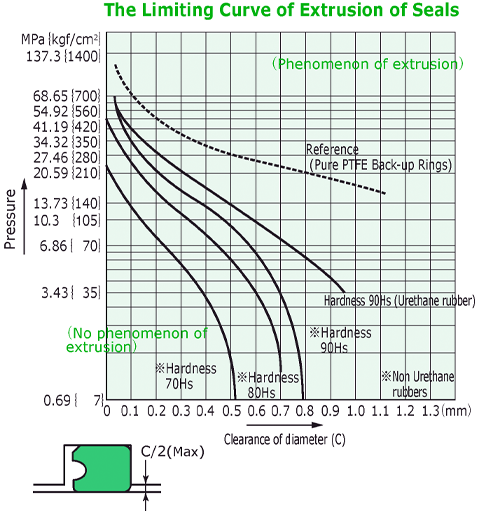

When the clearance of extrusion is too large and unbalanced with the applied pressure, the heel of the packing is bitten into the clearance and get damaged. Use back-up rings together with packings or narrow down the clearance according to The Limiting Curve of Extrusion of Seals. Chamfer the edge of the groove, and minimize eccentricity of pistons and rods. As the clearance tends to broaden when wear ring for the bearing are adopted, refer to The Limiting Curve of Extrusion of Seals to design appropriate clearance.

Appearance of packings

- The heel part of the packings is partly or thoroughly missing (Fig. A).

- In the primary stage, the bottom part of the packing shows a circumferential mark of extrusion.

Causes

- Clearance of extrusion (C/2) is too large (Fig. B).

- Excessive R chamfering on the groove edge (Fig. B).

Causes

- Correct the clearance of extrusion according to the specified dimension specified in The Limiting Curve of Extrusion of Seals. (Chart)

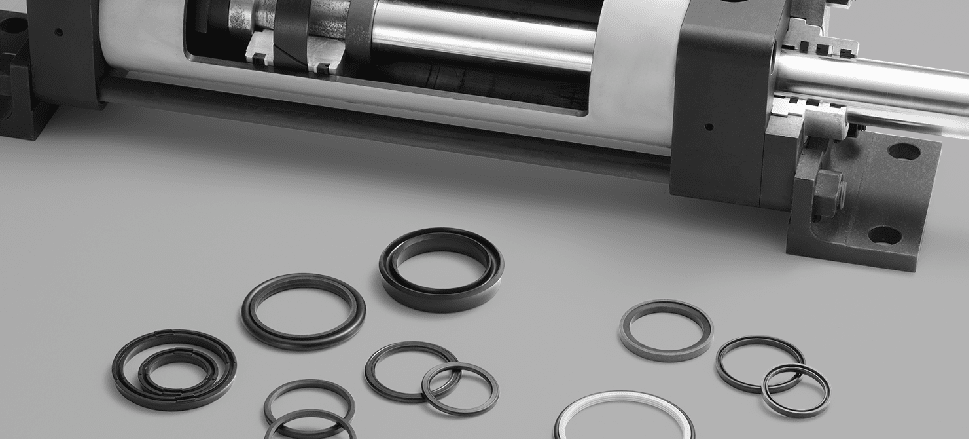

- Use back-up rings in combination with packings (Fig. C).

Highlights

- Chamfer on the edges of the groove appropriately. Eccentricity of pistons and rods should not be excessive.

- Use back-up rings when wear rings are used as the bearing.

- For high frequency operations or elevated temperature applications, even pressure and clearance of extrusion are below regular service range, use back-up rings.

- Control impulsive pressure by PG ring, pressure reducing ring.