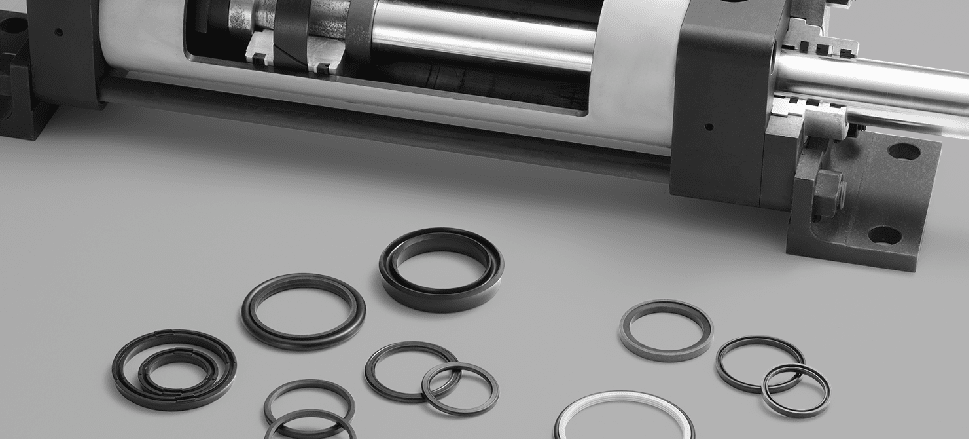

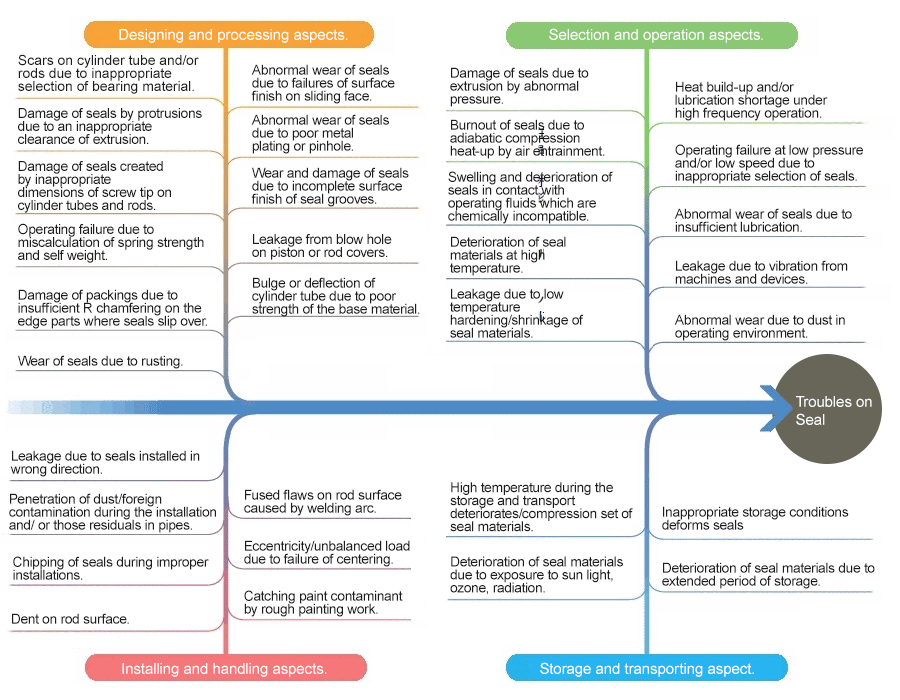

Cause of Trouble Outlook

Trouble of packings can generate by various causes from designing, processing and operating view points.

Followings are the causes in summery.

Determinations of cause by appearance of packings

Trouble of packings can generate by various causes from designing, processing and operating view points.

Followings are the causes in summery.

| Parts of packings Part Name |

Appearance of packings | Possible causes | Photos: |

|---|---|---|---|

| Lip top on contacting surface |

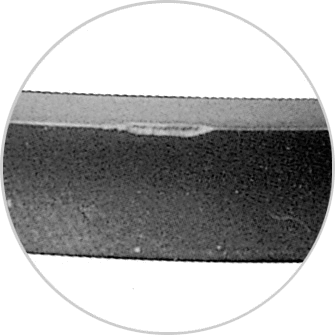

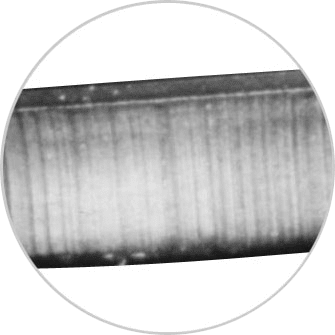

Fine wears | Scuff during the installation |

|

| Small chipping (tearing) | Scars at threaded part, width across flats and port where seals pass through |

|

|

| Initial stage of the damage by back pressure (View detail) |

|

||

| Circumference wear (includs partial wear) | Initial stage of wear and vertical scars (View detail) | ||

| Small deformation | Biting foreign substances (ex. lint and dust) | ||

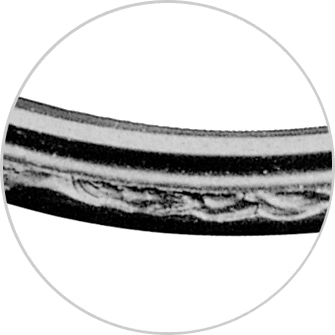

| Lip top on contacting surface |

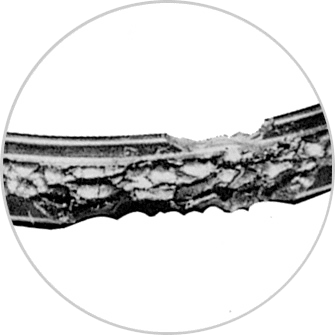

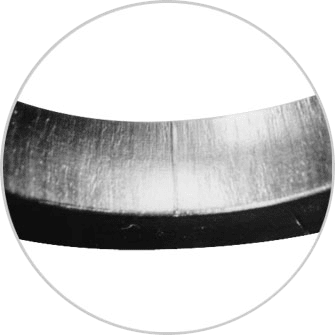

Damages and chippings | Damages by back pressure → Pursuing primary causes (View detail) |

|

| Lip top on contacting surface |

Chippings (Tear) Protrusion marks |

Damage by extrusion (View detail) Initial stage of damage by extrusion (View detail) |

|

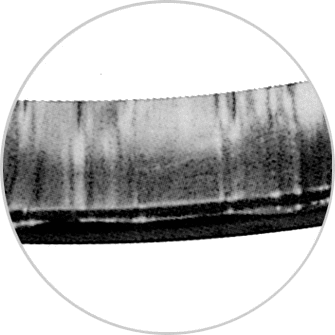

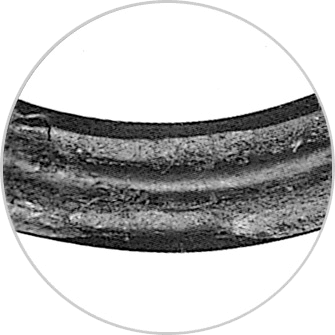

| Entire contact surface |

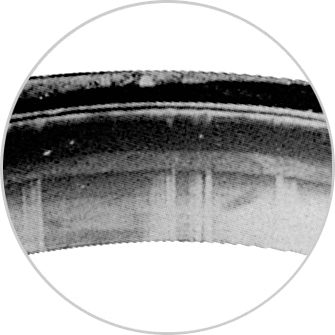

Deep vertical scars | (View detail) |

|

| Shallow vertical scars | (View detail) |

|

|

| Shallow and fine scars | (View detail) |

|

|

| A few vertical scars | (View detail) |

|

|

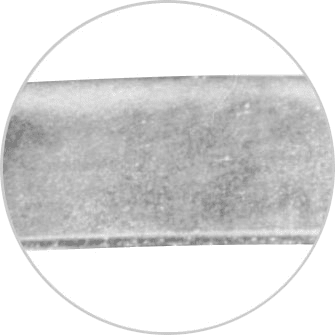

| Gloss wears | (View detail) |

|

|

| Mat wears | (View detail) |

|

|

| Eccentric wears | (View detail) |

|

|

| Circumferential wrinkles | Turned up lips Wear under constant pressurization & micro vibration condition |

|

|

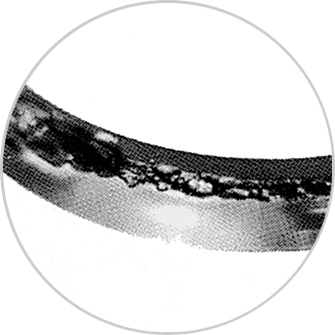

| Lip top on contacting surface |

Circumferential dints and scars | Initial stage of the damage by back pressure (View detail) |

|

| Wears (over the concave) | Turned up lips | ||

| Lip top of contacting side |

Fine wears Small chippings Circumference wear (includs partial wear) |

Scuff during the installation |

|

| Scars damaged at installation |

|

||

| Initial stage of wear and vertical scars (View detail) | |||

| Entire non-contacting surface |

Wears Pitted wears and scars |

Surface finish (roughness) of groove bottom Rust, incomplete casting and surface finish of groove bottom |

|

| Concave part | Cracks and breakage Circumferential wrinkles |

Surge pressure Turned up lips Increase of frictional force |

|

| Bottom surface | Wears | Rough surface finish of internal sides of groove | |

| Entire surface | Hardening, cracking and permanent strain | Excessive heat or attack by operating fluids | |

| Softning of material | Incompatibility of material with operating fluid | ||

| Partial hardening (Foaming) | Adiabatic compression of air in oil |

|

|

| Sticking (tend to melt) | Operating fluids attack materials |