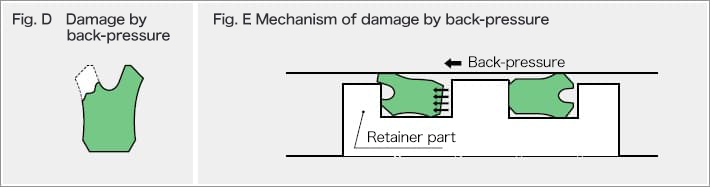

2.Damage by back pressure

For reciprocating hydraulic cylinders, 2 U-packings are installed in back-to-back position.Under certain conditions, back-pressure (reverse pressure or pressure built-up) is generated in the area between 2 U-packings. This back-pressure pushes the lip of the packings into the clearance between the cylinder tube and the retainer and generates damage to packings. Consider placing symmetric grooves to prevent pressure accumulation.

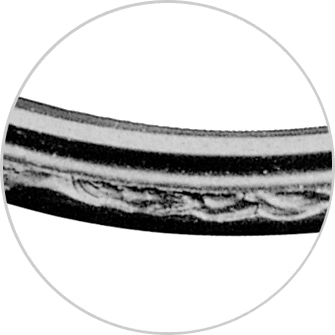

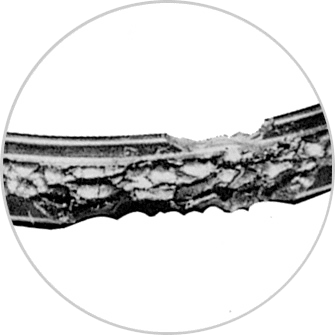

Appearance of packings

- Sliding lip tip of packing is missing partially or thoroughly on the circumference. (Fig. D)

- In the primary stage, pressed marks by retainer edge are observed on the lip top or on the taper part of the concave

Causes

- By primary causes of sealing performance degradation (missing of lip, vertical scar, wear or deterioration by heat), operating fluid passes through one of the packings and accumulates up between the packings. Back-pressure takes place and pushes the packings into the clearance between cylinder tube and retainer that damages packings.

Causes

- Eliminate primary causes, missing of lip, vertical scar, wear, deterioration by heat and others.

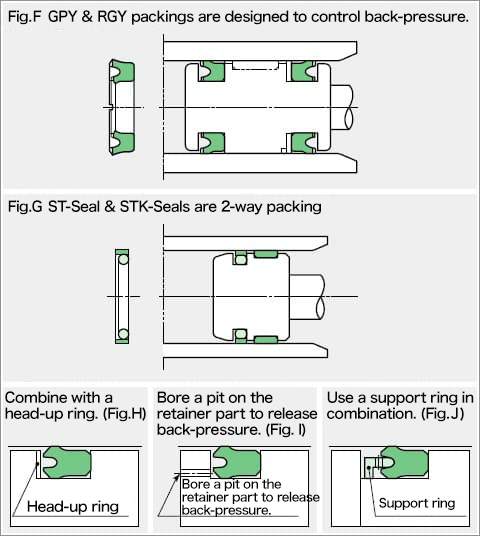

- Interchange packings to back-pressure free packings (Fig. F)

- Interchange packings to 2-way packings, typically ST or STK seals.(Fig. G)

- Combine with a head-up ring. (Fig. H)

- Bore a pit on the retainer part to release back-pressure. (Fig. I)

- Use a support ring in combination. (Fig. J)

Highlights

- Back-pressure frequently takes place under the condition that the operation stops long period while pressure stands unchanged.

- Back-pressure often occurs at high temperature/high frequency conditions.

- Lubrication grade of operating fluid can be responsible.