Installing Precautions

Technical informationHousing parts must be oil flushed thoroughly to secure cleanliness.

Do not use fuel oils or solvents, such as gasoline or kerosene, to clean packings. Prior to installation, wipe off or dry up these liquids completely to avoid contacts to packings.

For painting on rod cover part, mask dust seals (especially exposed lip part) so that the wet paint does not contact dust seals.

Apply operating fluid (lubrication oil used by the machinery) or grease (applicable one to the packing material) to packings and housing for smooth installation works.

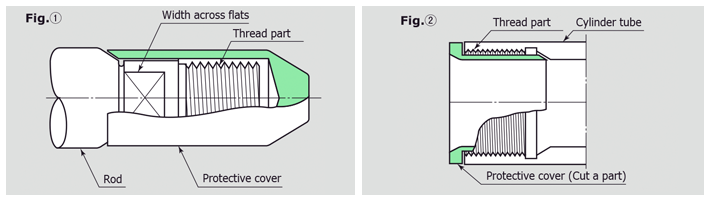

When lip of packing needs to pass over threaded part or width across flat, use a protective cover on the rod to avoid any contact with the delicate lip of packing. (See Fig. ① and ②)

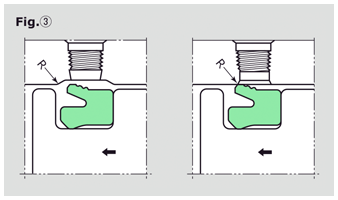

When passing packings over a port or bump surfaces, protect packings by placing escape shape around the port to avoid contact with packings or place R chamfer on the edge of port and pit. (See Fig. ③)

Tools like spatulas should be chamfered to be free from a sharp edge.

Verify the direction of the sealing components and install them on a correct direction.

Note: Direction of pressure can be referred to product dimension tables.

Avoid excessive stretching or deformation of packings during installation.

Once equipments are disassembled or repaired, packings must be replaced by new ones.

Installing Precautions for PTFE Products

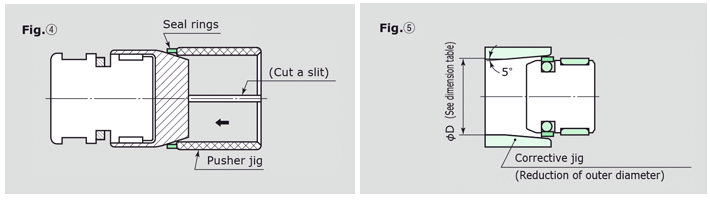

Consider using a jig to protect seals from damage when installation become a bit hard. Pay attention especially when seals need to pass over other grooves. (See Fig. ④)

Seal rings and PG-rings can easily be installed when they are warmed up and lose stiffness. Soak them in a hot oil or water at around 80℃. Safety measures for handling high temperature liquids are advisable.

When seal rings and PG-rings had excessive extension during installation and became too large to insert into cylinder tube, use a jig to reform them and restore to the original dimensions. (See Fig. ⑤)

Technical information

TECHNICAL INFORMATION