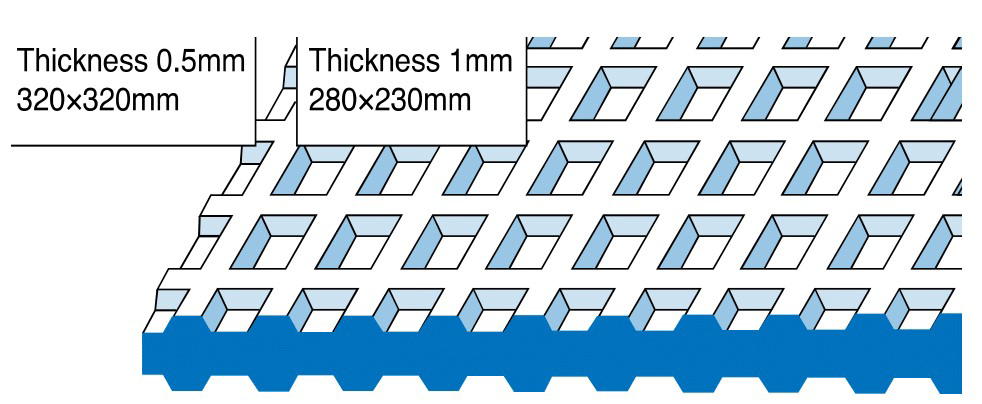

Profiles (Left section)

- Standard sheets are available in two thickness.

- Grid-surface gaskets are available in either standard sheets or customized shapes. Custom die-cut sheets also are available upon request while tooling costs are chargeable.