Profiles (Left section)

It is possible to search for products with set terms of use.

In addition, the search results may not always be effective for the actual usage environment and usage conditions. Please consider it as a reference standard.

Inquiries about more specific terms of use here from

| Standard Material | ||||

| Material codes | Pressure MPa {kgf/㎠} | Max. speed (m/s) |

Temperature range (℃) |

|

| NBR(RN906) | HSD-Packings〈Clearance of extrusion H9/f8〉 | 14 {140} | 1 | ー10~80 |

| w/Back-up rings | 21 {210} | 0.5 | ||

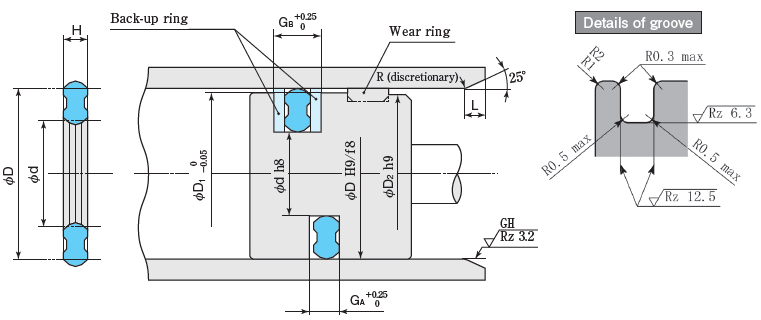

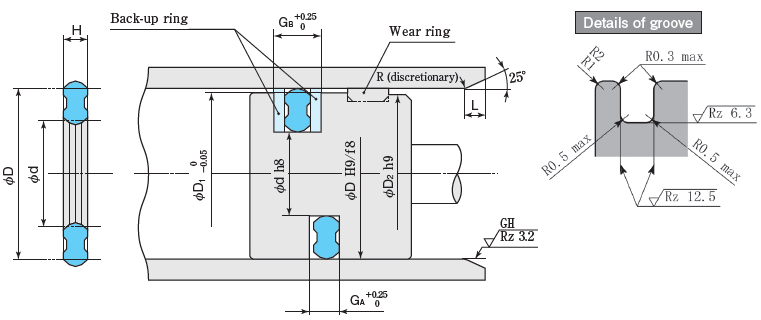

| Packings & Groove dimensions(Unit:mm) | Part No. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| D | d | H | GA | GB | D1 | D2 | L | Standard material(RN906) | Standard back-up ring(PT111) |

| 20 | 14 | 1.9 | 2.4 | 4.4 | 19.5 | 19 | 1.5 | HSD-20 | TCS-20×14 |

| 25 | 17 | 2.6 | 3.2 | 5.2 | 24.5 | 24 | 2 | HSD-25 | TCS-25×17 |

| 30 | 22 | 2.6 | 3.2 | 5.2 | 29.5 | 29 | 2 | HSD-30 | TCS-30×22 |

| 32 | 24 | 2.6 | 3.2 | 5.2 | 31.5 | 30.5 | 2 | HSD-32 | TCS-32×24 |

| 35 | 27 | 2.6 | 3.2 | 5.2 | 34.5 | 33.5 | 2 | HSD-35 | TCS-35×27 |

| 40 | 32 | 2.6 | 3.2 | 5.2 | 39.5 | 38.5 | 2 | HSD-40 | TCS-40×32 |

| 40 | 30 | 3.4 | 4 | 7 | 39.5 | 38.5 | 2.5 | HSD-40A | TCS-40×30 |

| 45 | 35 | 3.4 | 4 | 7 | 44.5 | 43.5 | 2.5 | HSD-45 | TCS-45×35 |

| 50 | 40 | 3.4 | 4 | 7 | 49.5 | 48.5 | 2.5 | HSD-50 | TCS-50×40 |

| 55 | 45 | 3.4 | 4 | 7 | 54.4 | 53 | 2.5 | HSD-55 | TCS-55×45 |

| 60 | 50 | 3.4 | 4 | 7 | 59.4 | 58 | 2.5 | HSD-60 | TCS-60×50 |

| 63 | 53 | 3.4 | 4 | 7 | 62.4 | 61 | 2.5 | HSD-63 | TCS-63×53 |

| 65 | 55 | 3.4 | 4 | 7 | 64.4 | 63 | 2.5 | HSD-65 | TCS-65×55 |

| 70 | 55 | 5.2 | 6 | 10 | 69.4 | 68 | 3 | HSD-70 | TCS-70×55 |

| 80 | 65 | 5.2 | 6 | 10 | 79.4 | 78 | 3 | HSD-80 | TCS-80×65 |

| 90 | 75 | 5.2 | 6 | 10 | 89.4 | 88 | 3 | HSD-90 | TCS-90×75 |

| 100 | 85 | 5.2 | 6 | 10 | 99.4 | 98 | 3 | HSD-100 | TCS-100×85 |